oem service

design

prototype

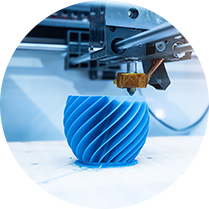

3D printing

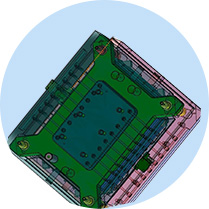

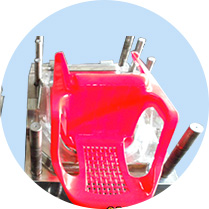

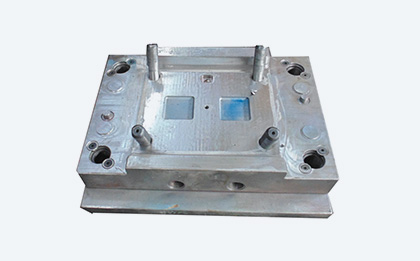

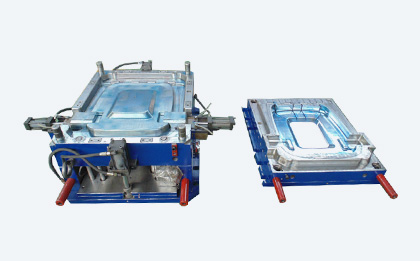

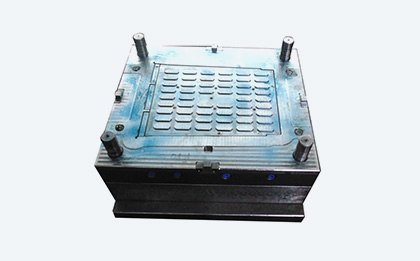

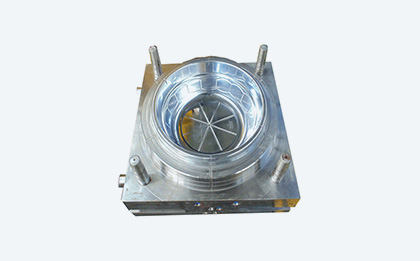

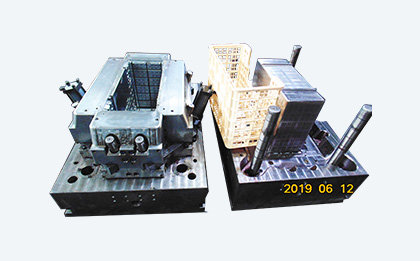

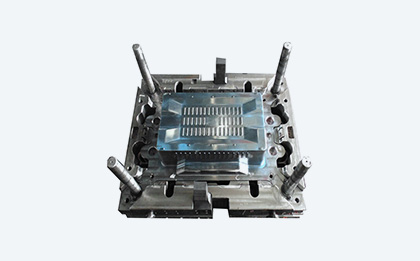

mould making

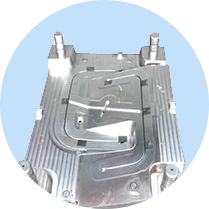

parts manufacturing

We offer one-stop plastic parts OEM service. We can offer you design, prototype, 3D printing, mould making and parts manufacturing service. Just give me your idea for plastic, we turns your idea to reality.

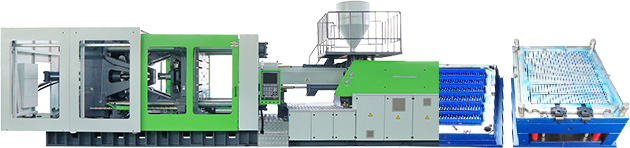

Our factory has 30 sets plastic injection machines from 80 tons to 2800 tons.

All the machines are equipped with automatic robot picking arms. Those arms improved the manufacturing efficiency . Also it reduced the risk of injury on-the-job.

According to customer needs, there is a specialist docking, communication with customers, and determine the design.

After determining the design scheme, both parties sign the contract.

Professional team for injection processing, R & D and production products.

After sample production, proofing test is carried out.

The quality inspection department conducts Standard Test on samples.

After the products pass the test, the production line will produce in batches.

Professional after-sales team, 7 * 24 hours online answering.

According to customer needs, there is a specialist docking, communication with customers, and determine the design.

After determining the design scheme, both parties sign the contract.

Professional team for injection processing, R & D and production products.

After sample production, proofing test is carried out.

The quality inspection department conducts Standard Test on samples.

After the products pass the test, the production line will produce in batches.

Professional after-sales team, 7 * 24 hours online answering.

Button

Cover of large dustbin

Body of large garbage bin

Knife plate

floor

Trash can parts

liquidizer

Trash can parts

basket

Baskets

Washbasin

Hollow turnover box

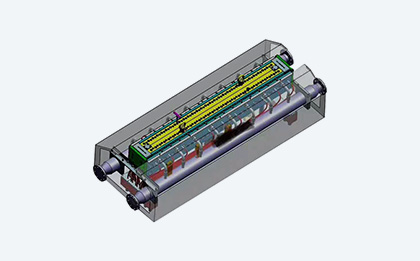

Melt blown cloth

Feed barrel

Paint barrel

chair

Corner tube

Turnover box parts

Our advantage

Excellent quality &

strong strengthYingward focuses on the processing and production of plastic

products, complete production process and product supervision and inspection process,

and strictly controls the quality of products.

Advanced technology &

complete productionYingward has a strong design, development and production

capacity, and has a modern production plant, forming an integrated production line.

Professional team

strict supervisionYingwode has a professional technical team to ensure

the production specification; at the same time, it has strict supervision and inspection

to ensure the product quality.

Service system

after sales worry freeYingward provides you with 7 * 24-hour exclusive

customer service, regular return visit to solve difficult problems, considerate

service and peace of mind.

+86-532-8467 7702

Q&A

Contact us

Qingdao Inorder Storage Equipment Co.,Ltd

Add: No.252, Chongqing Mid Rd, Licang, Qingdao, China

Tel: +86-532-8467 7702 / 8467 7703

Website: www.inorderstorage.com

E-mail: sales@inorderstorage.com

Plastic Storage Bin Plastic Boxes Plastic Pallet Dollies

Plastic Dividers kanban Label Cutting Tools Holder Picking Rack